HOT PRODUCTS

- All8

- Carbide Burrs / Products

- Carbide Drills Bit

- Custom Made Tools

- Carbide End Mills

- Custom PCD Drills

- Custom PCD End Mills

- Custom PCD Form/Profile Tools

- Custom PCD Reamers/Boring Tools

- End Mills For Aluminum/Brass

- End Mills For Carbon Fiber / Graphite /Zirconia /Ceramics

- End Mills For Stainless Steel

- End Mills For Titanium Alloy

- Famous Brands Tools/Accessories

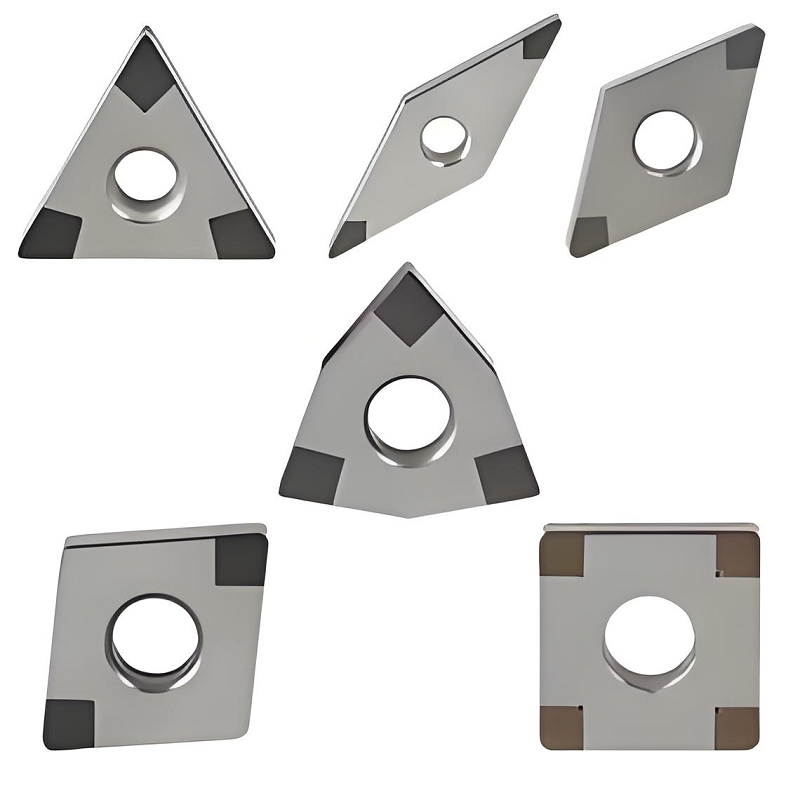

- PCD CBN Inserts

- All8

- Carbide Burrs / Products

- Carbide Drills Bit

- Custom Made Tools

- Carbide End Mills

- Custom PCD Drills

- Custom PCD End Mills

- Custom PCD Form/Profile Tools

- Custom PCD Reamers/Boring Tools

- End Mills For Aluminum/Brass

- End Mills For Carbon Fiber / Graphite /Zirconia /Ceramics

- End Mills For Stainless Steel

- End Mills For Titanium Alloy

- Famous Brands Tools/Accessories

- PCD CBN Inserts

INDUSTRIES WE SERVE

Provide integrated solutions for cutting tools

3C Electronics

3C industry tools are mainly used for frame processing, and the materials of the frame are mostly plastic and...

Automotive

What are the machining requirements for cutting tools in the automotive industry?In the modern mechanical processing chain, the automotive...

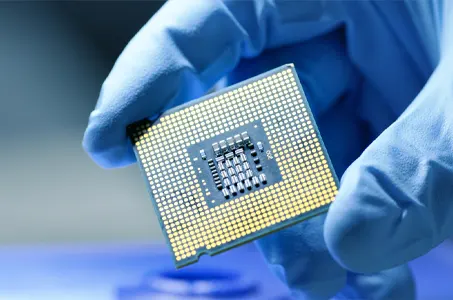

Semiconductor

1.Technical challenges of cutting tools in the semiconductor industry: 1)Breakthrough in material processing limitsThe hardness of third-generation semiconductor materials...

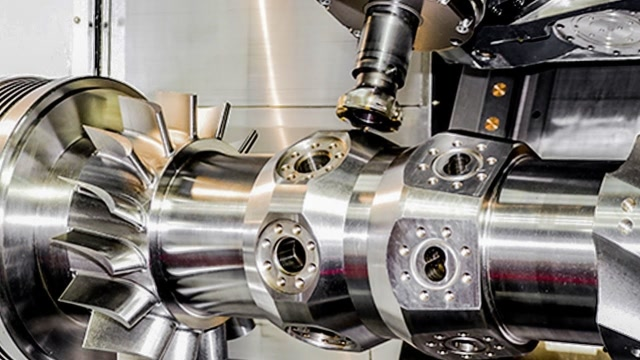

Machinery

The cutting tools in the mechanical processing industry will face various wear reasons during the cutting process. These reasons...

Wind Power

Key technical solutions for the use and optimization of cutting tools in the wind power industry

Mold

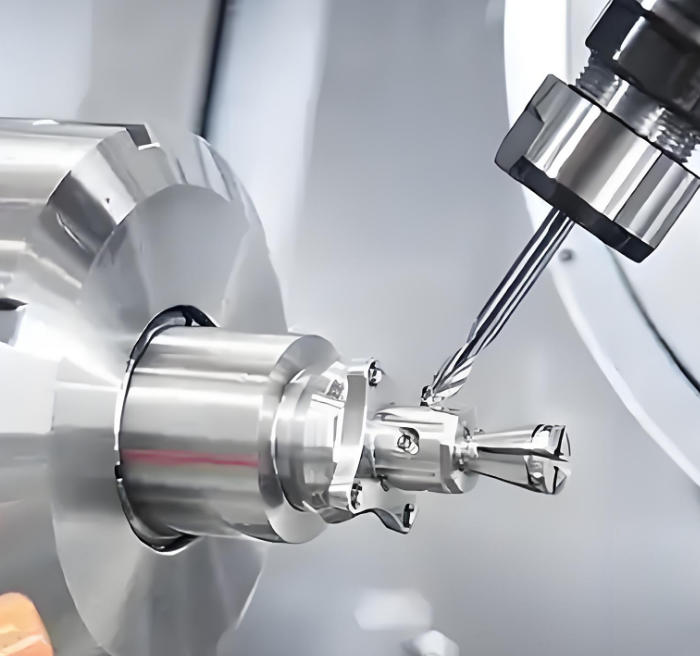

New Technologies for Cutting Tools in the Mold Processing Industry (Latest Developments in 2025) High precision composite machining technologyFive...

Rail Transit

The requirements for machining tools in the rail transit industry are mainly reflected in material properties, structural design, machining...

Aviation

1、 Processing of titanium alloy structural componentsX FLUTE Corn Milling Cutter: Designed with unequal helix angles and tooth pitch,...

Keeping Going With the Times / Advanced Manufacturing

Over 30 years of experience in the cutting field

FUJI Tools was founded in 1992 with a business policy dedicated to CNC machining center peripheral tools and cutting tools. In recent years, the company has invested more resources to establish a comprehensive operating environment and advanced manufacturing equipment in response to the cutting market demand, providing higher product quality and improved processing efficiency for mechanical processing industry workers. Our research and development focus is for future intelligent manufacturing related peripheral tools and cutting tools. In terms of human resource investment, we are working together with the University of Science and Technology to cultivate future professionals in the cutting field. In terms of resource investment, we include a 3250 square meter modern and automated manufacturing plant, European and Japanese production equipment, and inspection equipment. In response to the future development of technology and the application of high-temperature alloys and non-ferrous metal materials in various industries, JSH TOOLS has been introduced and merged to form JSH-FUJI Tools. The management team demonstrates the professionalism and service enthusiasm of Cutting Edge Solutions in quickly solving customer processing needs, and continues to develop and produce high-performance cutting tools to provide the best service for mechanical processing industry workers.

Our Market and Offices

Lastest News

Celebrating the 76th anniversary of the founding of the People’s Republic of China and the Mid Autumn Festival!

Wishing all Chinese around the world a happy holiday!

Application and Optimization of High Efficiency Ceramic Cutting Tools in High Temperature Alloy Milling

01 Advantages of Ceramic BladesHard alloy cutting tools encounter challenges when processing HRSA high-temperature alloys, and ceramic blade materials have become a powerful alternative. Whether it is turning or...

One of the future trends in metal cutting: dry machining

Dry machining is one of the important development trends in future metal cutting, which refers to a machining method that does not use or uses very little cutting fluid...

A more ideal aluminum material processing solution

~Abandoning the complexity of multiple cutting tools, only one milling tool is needed to improve aluminum material processing~The automotive industry is facing a dilemma regarding “weight”. For example, the...

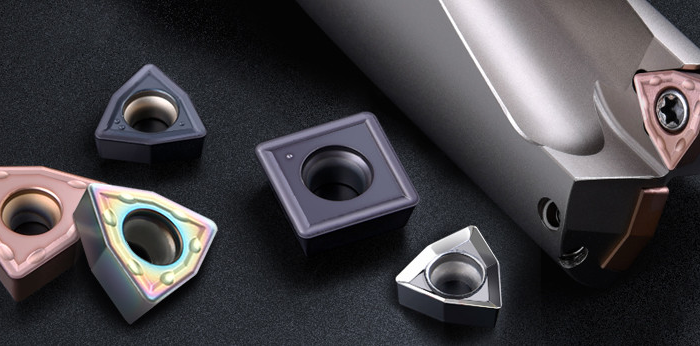

Precautions for use of tungsten carbide inserts

The characteristics of the tungsten carbide material itself determine the importance of the safe operation of the tungsten carbide foot cutting machine blade. Before installing the blade, take protective...

CIMT2025 Exhibition Review | Cutting Tools are Moving from Product Offering to Value Services

CIMT2025, as the largest professional event for machine tools in the world in the past decade, has an exhibition area of 310000 square meters and a total of 345864...

Comprehensive Comparative Analysis of Top Global Metal Cutting Tool Brands

▲ Innovation and Strength of Sandvik CoromantSandvik Coromant, a globally renowned supplier of metal cutting tools, not only provides excellent tool products, but also leads the way in tool...

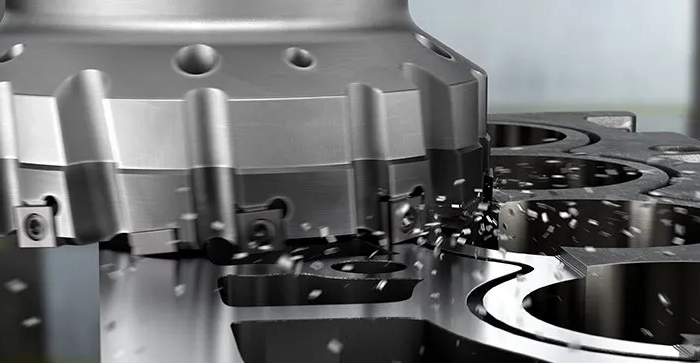

JSH-FUJI & Factory ‘s New quipments arriving!

From unpacking to testing, everyone ‘rolled up their sleeves and worked hard’! The precision gears of the new equipment hide our small goals for 2025- zero error and high...